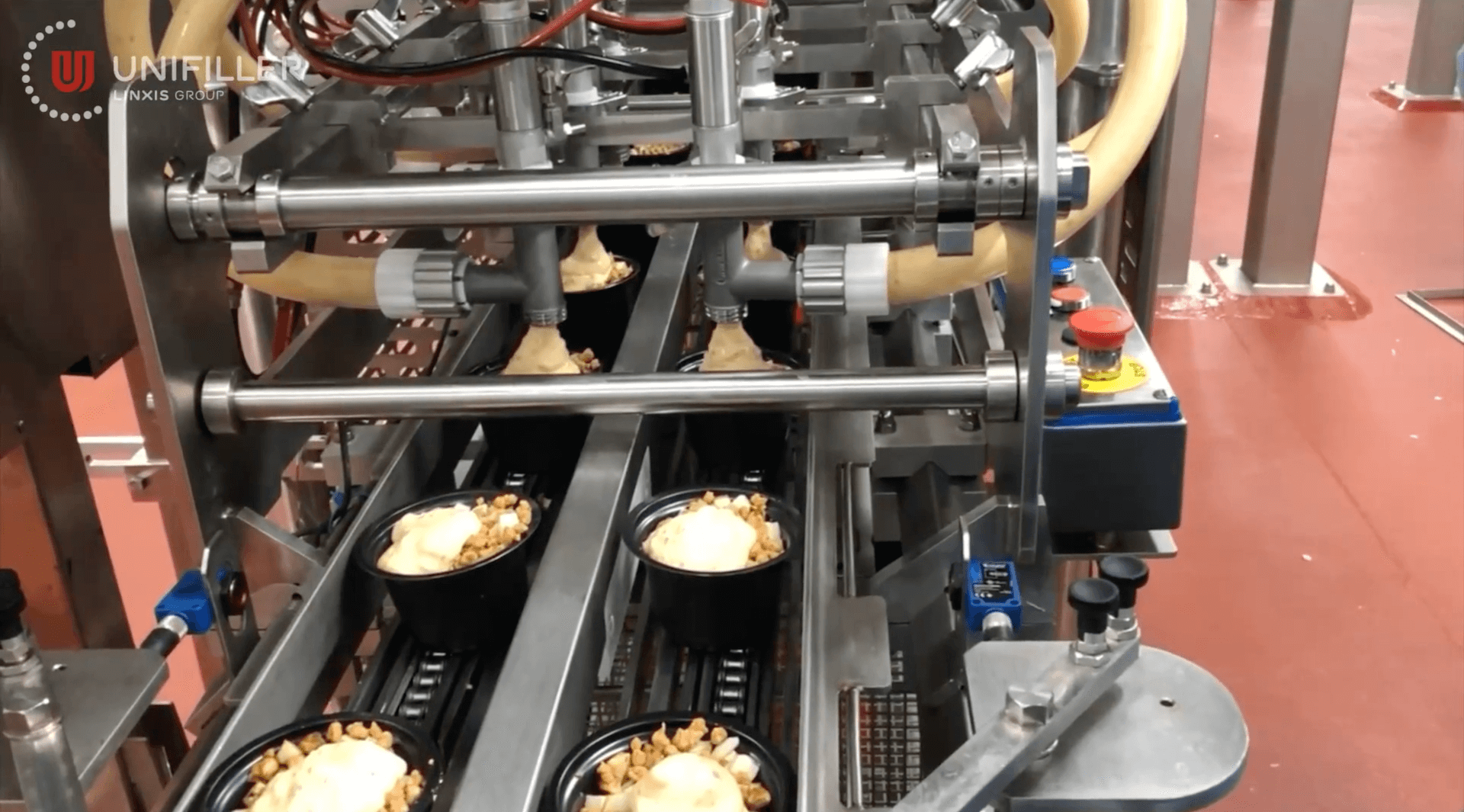

Industrial Food Production Equipment

Stand-Alone Depositing Machines to Fully Integrated Lines

From stand–alone food depositing machines and transfer pumps to fully integrated production lines, Unifiller can develop an automated system perfect for you. Our depositing machines feature upgraded pneumatic control systems that substantially reduce corrosion caused by moisture build–up, caustic cleaning processes, and daily wear and tear, making them ideal for environments with extreme temperature requirements. A patented SV product valve, large openings, and passages allow for safe depositing of larger chunks up to 1.5”.

Our equipment will work with:

- Packaging, processing form, fill & seal lines

- Shear sensitive – gentle on your product

- Liquids with cubes, chunks or particulates

- Kettles and cook/chill

- Sandwich spray and filling

- Add spreader nozzles, injection needles, heated hopper, agitators & more.

Attachments and Section 179 Deductions for this Machine

In this video: Sauces, Chicken, Ready Meals, Pasta, Macaroni, Tortellini, Steak, Ribs, Salsa, Meat, Head Cheese, Tuna, Sandwiches, Kimchi.

Videos are for demonstrative purposes. Similar products may require further testing. Actual machine may differ slightly.

Thermoform Depositing

Tray Sealing Lines

Travelling Bridge

SPECIFICATIONS

SPEED

Adjustable

0 – 50 ft per minute

DEPOSIT RANGE

Varies

PARTICLE SIZE

Varies

POWER

Varies

WASHDOWN

Easy Washdown

TOOLS

Minimal Tooling